Metallurgical bonding is a process that creates composite materials by combining two or more distinct metals or metal alloys. The resulting clad metal has improved mechanical, physical, and chemical properties compared to its components. They are used in various high-performance applications, including aerospace, defense, automotive, medical, and energy. This article discusses a lot more on the versatility of clad metals. Read further to know about it.

Advantages

They possess several advantages over traditional materials such as solid metals and alloys. Bonded metals can provide a cost-effective alternative to solid metals that are expensive or difficult to fabricate. Secondly, it can be tailored to meet specific design requirements, combining the strength and durability of one metal with the corrosion resistance or conductivity of another. Additionally, they can offer improved heat transfer, better electrical conductivity, and enhanced surface properties.

Types

Bonded metals can be produced in various ways, each resulting in a different type of material. The most common methods include roll bonding, explosion bonding, and electroplating. Roll bonding involves passing two sheets of metal through a set of rollers to create a strong bond. Explosion bonding consists in using explosives to bond two layers of metal together. Electroplating involves applying a thin layer of one metal onto the surface of another.

Applications

Aerospace and Defense

Clad metal is extensively used in the aerospace and defense industries for its strength, durability, and lightweight. It is used in aircraft structures, heat exchangers, and fuel tanks in aerospace. In defense, it is used in armor plating, blast shields, and vehicle structures.

Automotive

It is also used in the automotive industry, where its light weight and strength make it an ideal material for various applications. Bonded metals are used in engine components, body panels, and heat exchangers.

Medical

It is used extensively in the medical industry for its biocompatibility and corrosion resistance. It is commonly used in implants, surgical instruments, and medical devices.

Energy

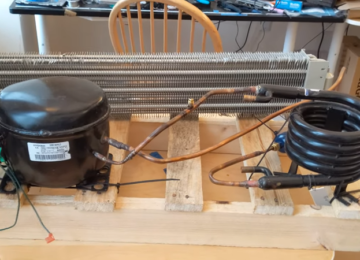

It is also an ultimate energy industry need for its high-temperature and corrosion resistance. It is commonly used in heat exchangers, boilers, and power generation equipment.

Future of bonded Metal

The future of bonded metal is promising, with ongoing research and development aimed at expanding its use in various industries. As new applications and requirements emerge, it will continue to be a versatile and adaptable solution for high-performance applications.

As technology advances and the demand for more efficient and effective materials increases, these metals are expected to play an even more significant role in shaping the future of manufacturing and engineering. Ongoing research and development efforts are focused on improving the properties and performance of these metals, such as enhancing their corrosion resistance, strength, and thermal conductivity.

Additionally, developing new bonding techniques and technologies enables the creation of bonded metals with increasingly complex and varied layer configurations, expanding their possible applications. With their unique combination of properties and versatility, they are poised to play an essential role in meeting the challenges and opportunities of the future.

Thus, clad metal is a versatile material that offers a range of benefits for high-performance applications. With their unique properties, they can provide a cost-effective alternative to solid metals and alloys while also offering improved performance characteristics. These bonded metals are increasingly used in various industries, from aerospace and defense to automotive and medical. While metal fabrication can be challenging, ongoing research and development are paving the way for even more innovative applications of this material.