Your manufacturing operations’ effectiveness and quality might be greatly impacted by your choice of Electrical Discharge Machining (EDM) technique.

With three primary EDM machining methods—Wire EDM, Sinker EDM, and Hole Drilling EDM—each offering distinct advantages, it’s important to understand which one is best suited to your business needs.

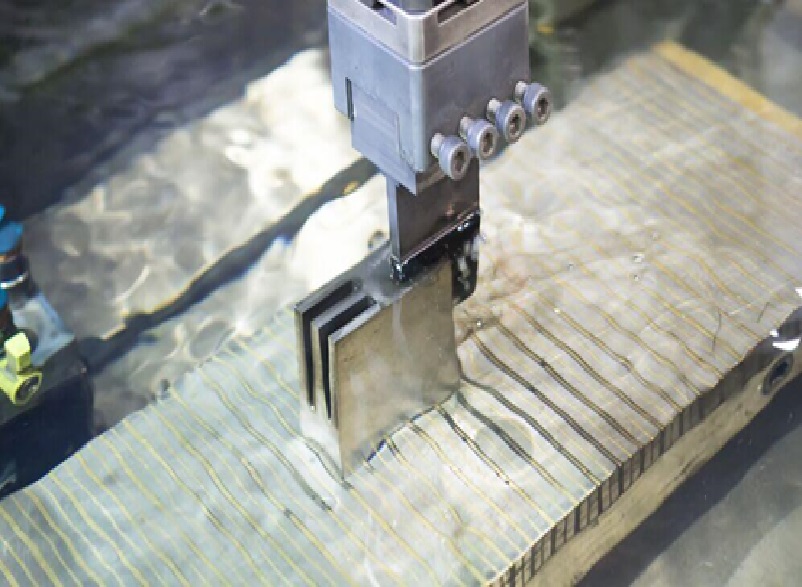

Wire EDM

Wire EDM uses a thin, electrically charged wire to cut through conductive materials with exceptional precision. This method is ideal for machining intricate shapes, tight tolerances, and delicate parts.

Industries such as aerospace, medical devices, and electronics often rely on Wire EDM due to its ability to produce complex geometries without compromising accuracy.

| Advantages | Disadvantages |

| Achieves tolerances as tight as ±0.0001 inches | Slower cutting speed compared to other EDM methods |

| Excellent for complex and fine details | Limited thickness of material that can be cut |

| Works with hard materials like titanium, tungsten, and tool steel | Higher operational cost due to fine wire |

Sinker EDM

Sinker EDM, sometimes referred to as Ram EDM, creates cavities in the workpiece using an electrode that is specially designed. This method is quite flexible and works well for making dies, molds, and pieces with complex or deep cavities.

It is widely used in mold making, automotive, and aerospace industries where precision cavities are required.

| Advantages | Disadvantages |

| Ideal for producing deep cavities and complex shapes | Slower process due to the need for custom electrodes |

| Can work with materials like steel, carbide, and aluminum | Higher upfront cost for tooling and electrodes |

| Custom electrode shapes offer flexibility in design | Longer setup time due to custom electrode creation |

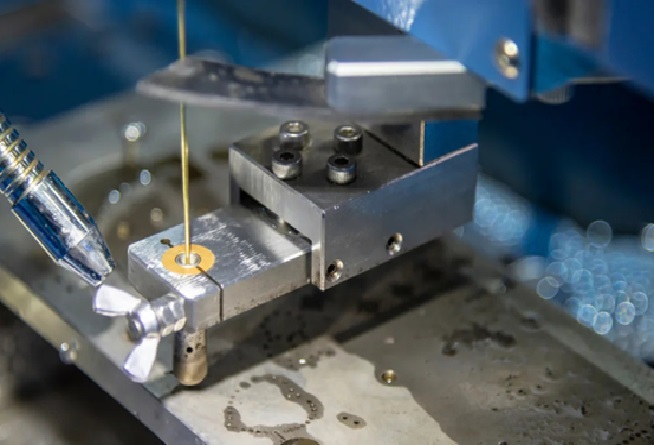

Hole Drilling EDM

Hole Drilling EDM specializes in creating small, accurate holes in conductive materials.

This process is used in industries like aerospace and medical devices for producing cooling holes, fuel injectors, and other components that require fast and precise drilling.

| Advantages | Disadvantages |

| Efficient for drilling small holes, even in tough materials | Limited to hole drilling applications |

| Capable of drilling holes as small as 0.1 mm in diameter | Equipment can be costly for high-volume production |

| Fast production times | Less versatile compared to Wire and Sinker EDM |

Comparison of Wire EDM vs. Sinker EDM vs. Hole Drilling EDM

To better understand which EDM process may be the right fit for your business, here’s a comparison of the three methods:

| Feature | Wire EDM | Sinker EDM | Hole Drilling EDM |

| Best for | Intricate, complex shapes | Deep cavities, molds, and dies | Small, precise hole drilling |

| Precision | Extremely high, up to ±0.0001 inches | High, dependent on electrode shape | High for small holes |

| Speed | Slower, especially for thicker parts | Moderate, slower due to electrode setup | Fast for small holes |

| Material Thickness | Limited by wire length | Can handle thicker parts | Primarily for small hole drilling |

| Cost | Higher operational cost | Higher upfront tooling cost | Expensive equipment for specific use |

Which EDM Method Is Best for Your Company?

Deciding on the best EDM process depends on your specific requirements. If precision and intricate designs are your priority, Wire EDM will deliver the best results.

For deep cavities or mold-making, Sinker EDM offers unmatched versatility. Meanwhile, if you need to create small, precise holes quickly, Hole Drilling EDM is the ideal choice.